John C. Kessel

Biography

John C. Kessel has experience in home restoration, remodeling and home building since 1979. John grew up learning the trade from his father’s company. John is a licensed builder, in the state of Michigan. His building knowledge gives him the expertise in how buildings are structured, vented and how possible moisture intrusions can affect mold growth.

TC MOLD MAN, A Division of Custom Interiors, was built on the strengths of John’s experience. As a reputable contractor serving northern Michigan, John has been heavily involved in every aspect of mold inspections and remediation as well as the re-construction phase.

Credentials

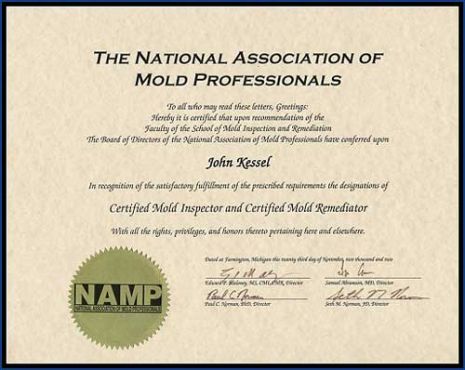

- Certified in mold inspection, sampling and remediation through the National Association of Mold Professionals. Past co-founder of Leviticus Corporation.

- Assisted with the deployment and training of Leviticus Software to NAMP Headquarters and throughout associated business and franchises.

- Helped to design and facilitate custom laboratory analytical test result software for Integrated Microbial Services Laboratory in Detroit, Michigan.

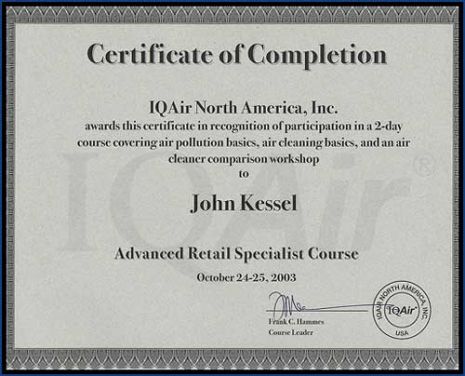

- Attended IQAir North America course covering air pollution basics, air cleaning basics and air cleaning comparison workshop in Los Angeles on October 24th & 25th of 2003.

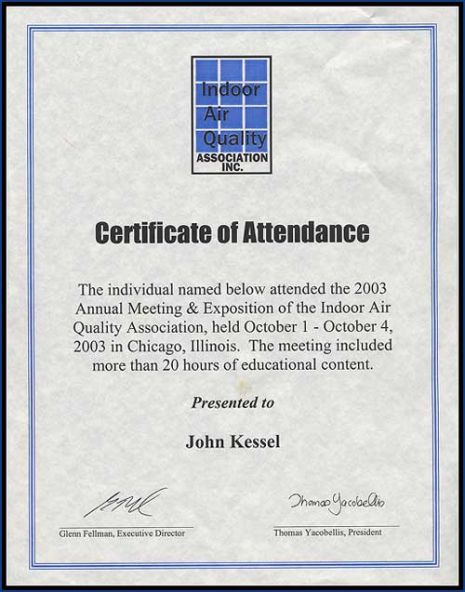

- Exhibitor of Leviticus software at the Indoor Air Quality Association (IAQA) Expo demonstrating Leviticus software and attending all educational meetings on October 1st thru 4th of 2003 in Chicago Illinois.

- Exhibitor of Leviticus software at the American Conference of Industrial Hygienists (ACGIH) Expo demonstrating Leviticus software and attending all educational meetings on November of 2003 in Orlando Florida.

- Invited to review, give input and instruct on the California State University’s 40 Hour Mold Inspection and Remediation course in San Marcos California.

- John has met with and spoken to dozens of microbiologists throughout the country on sampling methods from Aerobiology Laboratory, IMS Laboratory, AeroTech Laboratory, North Eastern Laboratory, EmLabs Laboratory just to name a few.

- As of September of 2004, John C. Kessel was appointed to the Environmental Education Foundation’s Advisory Group on Indoor Air Quality, convened under a sole source contract by the U.S. Environmental Protection Agency (EPA).

John has reviewed and is well versed in the following mold inspection and remediation guidelines:

- New York City Guidelines

- IICRC – S520 (Attending National Meeting on the IICRC – S520)

- Texas State Legislation

- EPA I-BEAM Software

- California State San Marcos Mold Inspection and Remediation Curriculum

- National Association of Mold Professionals

- Exterior entry hatches or doors.

- Joints between the top of the foundation wall and the mud sill, between the mud sill and the rim joist and between the rim joist and the sub-floor.

- Around ducts, pipe conduits or other penetrations through the wall or rim joist.

Foundation walls may be insulated on their outside, inside or, in the case of insulated concrete forms, both sides. Insulating on the outside keeps the foundation wall’s temperature and moisture content more uniform throughout the year. If insulation is applied to the interior side of a basement wall, materials that can act as vapor barriers (e.g., polyethylene film, foil-faced paper or vinyl wall covering) should not be used. The vapor barrier can trap any moisture present in the foundation wall, creating moisture and mold problems on the wall’s interior surface.

Moisture and humidity issues are not eliminated once the crawl space is sealed. In the sealed environment, a small amount of moisture or humidity can cause a significant moisture problem unless provisions are made for some level of air exchange with conditioned air. This is accomplished with mechanical ventilation of the crawl space in essentially two ways:

- An exhaust fan inserted into the crawl space wall removes a small amount of air from the crawl space and it is replaced by drawing a small amount of conditioned air from the living space (through cracks and other openings in the floor above into the crawl space). If radon-resistant construction is necessary, do not implement this option because it can interfere with the operation of the mitigation system.

- A small amount of conditioned air (minimum 1 cfm per 50 sq. ft. of crawl space floor area) is blown directly from the heating and air-conditioning system (from equipment located in the living space above and ducted to the crawl space, or directly from HVAC equipment located in the crawl space).